Pulse type bag filter

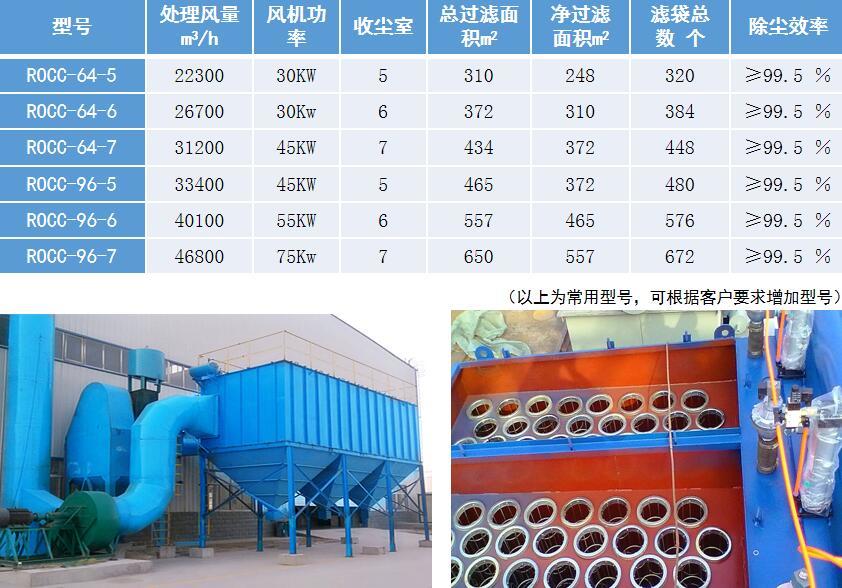

Air box pulse bag filter is a high-efficiency dust collector. It integrates the advantages of various dust collectors with chamber back blowing and pulse dust cleaning, overcomes the shortcomings of insufficient chamber back blowing dust cleaning intensity, pulse dust cleaning and filtration at the same time, and greatly improves dust removal efficiency. It is a large-scale dust removal equipment with large air volume, good dust removal effect, high dust removal efficiency, reliable operation, convenient maintenance and small footprint. It is widely used in cement, metallurgy, chemical industry, machinery and civil boiler waste gas dust collection. ★Product Structure The dust collector is mainly composed of an upper box, a middle box, an ash hopper, a side air inlet uniform flow settling chamber, a bracket, a filter bag, a skeleton, a blowing system, a dust cleaning solenoid valve, a pneumatic off-line dust cleaning and air closing valve, a control system, and a dust unloading device. ★Product performance and characteristics 1. The structure has high dust removal efficiency, and the fan air volume and full pressure are reasonably selected to ensure the dust removal effect of each node of the production line. 2. Ash cleaning is carried out in different chambers in turn, that is, so-called off-line ash cleaning. When a certain chamber carries out ash cleaning by spraying, the filtering air flow is cut off, thus avoiding the secondary flying of dust caused by spraying ash cleaning. ★Equipment selection and technical parameters ★Parts related technical parameters

Classification:

Key words:

- Product Description

-

★ Product overview

Air box pulse bag filter is a high-efficiency dust collector. It integrates the advantages of various dust collectors with chamber back blowing and pulse dust cleaning, overcomes the shortcomings of insufficient chamber back blowing dust cleaning intensity, pulse dust cleaning and filtration at the same time, and greatly improves dust removal efficiency. It is a large-scale dust removal equipment with large air volume, good dust removal effect, high dust removal efficiency, reliable operation, convenient maintenance and small footprint. It is widely used in cement, metallurgy, chemical industry, machinery and civil boiler waste gas dust collection.

★ Product Structure

The dust collector is mainly composed of an upper box, a middle box, an ash hopper, a side air inlet uniform flow settling chamber, a bracket, a filter bag, a skeleton, a blowing system, a dust cleaning solenoid valve, a pneumatic off-line dust cleaning and air closing valve, a control system, and a dust unloading device.

★ Product performance and characteristics

1, the structure of high dust removal efficiency, fan air volume and full pressure selection is reasonable, to ensure that the production line.The dust removal effect of the node.

2, the use of sub-room turn for ash removal, that is, the so-called off-line ash removal, when a room for blowing ash removalWhen the filter air flow is cut off, the secondary flying of dust caused by spraying ash is avoided.

★ Equipment selection and technical parameters

★ Parts related technical parameters

Related Products