Steam automatic pre-foaming machine

Pure steam pregenerator can set stirring time and steam time in time according to process requirements. The barrel body adopts closed constant pressure foaming, which has high thermal efficiency, saves steam, and saves energy by 50% compared with continuous pregenerator. The density is stable and the particles are uniform. It can also be applied to the pre-foaming of EPS, EPMMA and STMMA copolymerization.

Classification:

- Product Description

-

★ Product overview

Pure steam pregenerator can set stirring time and steam time in time according to process requirements. The barrel body adopts closed constant pressure foaming, which has high thermal efficiency, saves steam, and saves energy by 50% compared with continuous pregenerator. The density is stable and the particles are uniform. It can also be applied to the pre-foaming of EPS, EPMMA and STMMA copolymerization.

Name

Unit

Argument

Barrel body

Dimension

mm

φ450*800

Volume

m³

0.13

Steam

Entrance

mm

DN25

Working pressure

MPa

0.03~0.1

Compressed air

Entrance

mm

DN25

Working pressure

MPa

0.4~0.8

Installed power

5.7KW

Production efficiency

18~25Kg/h

Floor space

3.5*2*3m

★ Product structure

1、Preserver host

2、Fluidized bed

3、Automatic weighing system (weighing, quantitative)

4、Feeding system (fan *3)

★ Main functions and advantages

Equipped with hot air drying system, non-caking, pre-formed raw materials dry, uniform, shorten the natural aging of the aging time.

The machine adopts PLC programmable controller and touch screen control, automatic feeding, automatic electronic metering, automatic control of the temperature and pressure of the barrel, self-dynamic measurement of material level, etc., to ensure the automatic cycle production of the machine.

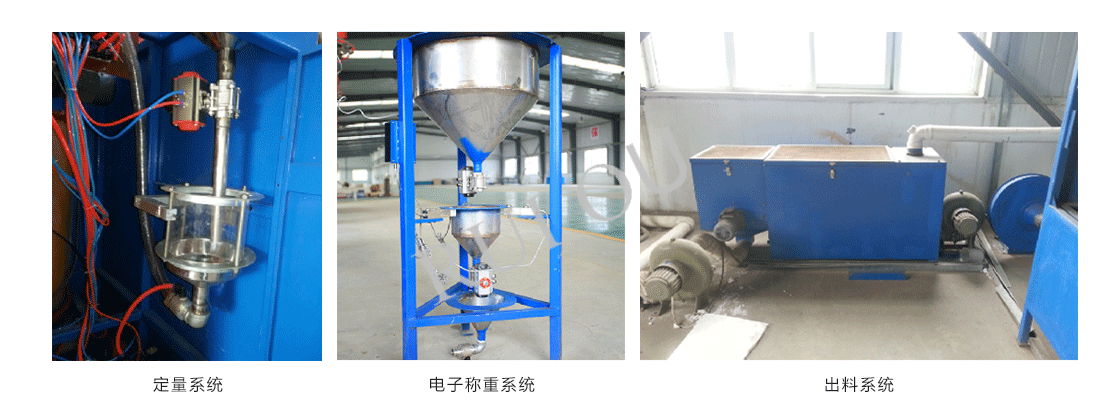

★ Automatic weighing system

The automatic weighing device adopts the most sophisticated weighing sensor and instrument in China. The weight can be set on the instrument, and the instrument can accurately control the weighing value to ensure accurate feeding.

The electronic weighing and quantitative feeding system is composed of three different sizes of hopper, the top hopper is the raw material pouring place, the middle of the small hopper is the raw material weighing place, and the bottom hopper is connected with the loading valve.

★ Automatic dosing system

The automatic metering device controls the feeding parameters by setting the feeding time. Parameters can be arbitrarily set according to the production situation to achieve the effect of automatic feeding.

The electronic quantitative feeding system is composed of three hoppers: raw material hopper, upper feeding hopper and lower feeding hopper, and then enters the heating barrel body through the feeding valve.

★ Discharge system

The discharge system consists of: fluidizing buffering machine, discharge fan, discharge fan and discharge door connection, discharge fan and vulcanization buffering machine connection, drying fan, vibration and screening system, material conveying fan and so on to form a fully automatic circulation foaming system. Ensure that the discharge material can be dried after pre-foaming and enter the curing bin smoothly.

Related Products