Casting Process of Lost Foam for Grinding Ball

Release time:

2022-07-01 17:47

Source:

1Foreword

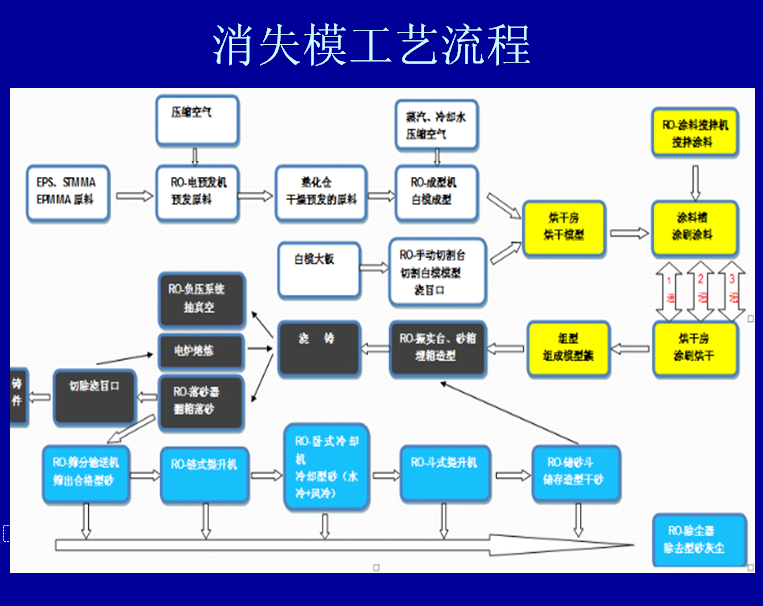

Advantages and Process Characteristics of Lost Foam CastingEspecially suitable for the casting of grinding balls,It gives full play to the characteristics of investment casting that can be cast in series.,And no crusts,Have a higher process yield,High production efficiency,High product quality advantages. Lost foam casting grinding ball,It is a relatively simple type of lost foam casting process.

Lost foam casting grinding balls must meet the national standards for grinding balls. As well as the Ministry of Power, the Ministry of Building Materials and other standards. SimultaneouslyThe manufacturer of grinding balls complies with the above standards.,Combined with user requirements,According to local raw materials,Adjust appropriately,For example, near the production of rare earth mining area or other mineral materials with rare earth elements,The mechanical properties and service properties of the grinding balls can be improved by adding the right amount of people when casting the grinding balls.

2Making and stringing of white mould

2.1Selection of foam pattern materials

Foam plastic is selected as the pattern material for lost foam casting. There are many kinds of foam plastic. Foam plastic required for lost foam pattern needs certain conditions, so few can meet the requirements. Because when foam plastics are applied to the field of lost foam casting, the following conditions must be met:

(1) Low density and high strength;

(2) Easy to vaporize, less residue of high temperature decomposition;

(3) easy to shape, can get a smooth surface appearance.

EPS(Polystyrene) has high strength, small gas emission, the main decomposition products are aromatic hydrocarbons with large molecular weight, more gas, more elemental carbon, cheap, and widely used. Domestic use is moreEPS(Polystyrene), and because polystyrene has good foam molding properties, so, in the use of foam molding, mass production, multi-choice polystyrene or polystyrene and polymethyl methacrylate (PMMA) of copolymers. In addition to foamingPMMAHigh hardness, brittleness, not easy to obtain low density appearance also makesPMMANot suitable for foam molding. Therefore, suitable materials can be selected according to the actual situation of the company.

2.2white mould forming

It is used more in China.EPS (polystyrene) as an example to introduce:

(1) Pre-foaming:

Before molding, the resin particles (raw material particles) are pre-sent to the appropriate density.18g/L~22g/LGenerally, it is heated by steam or electric heating.

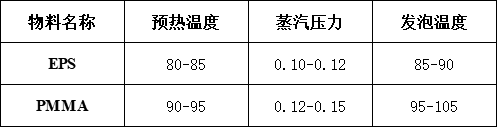

(2)Pre-foaming process parameters (see Table2-1):

Table2-1 Operation parameters of SJ-KF-450 type intermittent steam pre-generator

AdoptEPS, preheating temperature80 ℃, steam pressure0.1MPa, foaming temperature90 ℃, the feeding time is usually set3-5sHeating time150-200s, holding time15-30s. After cooling, the discharge beads need to be matured and dried. The optimum curing temperature of the beads is23-25 ℃, the time is12-24h.

2.3molding process

Shrinkage of the pattern material, usingThe recommended shrinkage rate for EPS is0.3%~0.4%.

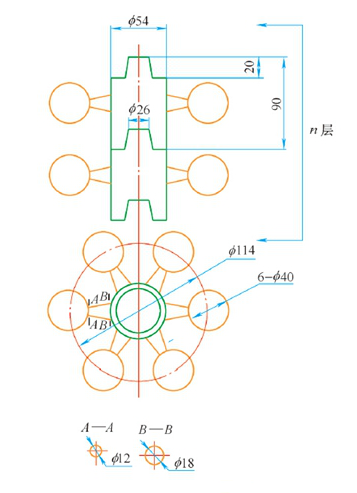

Lost foam casting grinding ball like investment casting, can stringEPSwhite mold ball,Bonded sprue( E P SGreat)Can be square, pentagonal, hexagonal, polygonal, circular. Its size, length andE P SThe number of balls in each row and the bonding of the upper and lower layers,According to the process of pouring grinding balls in each factory,And the capacity of the smelting equipment determines the arrangement of several groups of strings per sand box.EPSBall(Size, number, weight and gating system)And set. For example: each layer6The ball is evenly distributed. The production rate of multi-vertical string process is80 %Above. Figure2.1,2.2.

Figure 2.1

Figure2.2

2.4Design of gating system

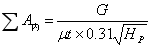

Because the piece belongs to small and medium-sized castings, the pouring time of the pouring system, the cross-sectional area of the inner runner and the cross-sectional size of each component of the pouring system are calculated as follows:

∑FStraight:∑FHorizontal:∑FInside=1.4:1.2:1.

(1) Pouring time

T= G½ G⅓

T=10.6s(Tis the pouring time);

(2) Calculation of the cross-sectional area of the in-gate

by hydraulics calculation formula:

According to the design of the gating system shown in the figure can be2.2 shown in the figure, the dimensions of each component section of the gating system are calculated according to the above formulas. The top injection method with high process yield is used for pouring.

2.5white die bonding

The appearance is divided into two parts and played by a molding machine, so the two parts should be combined. After the combination, the gate cup, the inner gate, the runner and the foam pattern parts are bonded with cold glue.

3Selection of coatings

The yellow zone is the process of preparing the lost-form coating. Lost foam coating is an important part of lost foam casting and is one of the key factors. Different from other casting coatings applied to the cavity, the lost foam coating is applied to the foam model, so a special coating is required. Lost foam coatings are generally made of refractory materials, binders (solvents), surfactants, suspending agents, thixotropic agents and other additives.

3.1Coating composition

(1)refractory material

Refractory material determines the refractoriness, chemical stability, and thermal insulation properties of the material, which is the backbone of the lost foam coating. The castings are cast iron, and bauxite, kaolin clinker, quartz powder and brown corundum powder are often used as refractory materials.

(2)Binder

Reasonable selection of organic binder and inorganic binder can ensure the high strength and high permeability of the coating. Among them, bentonite, silica sol, water glass, phosphate and the like are commonly used as inorganic binders. This time calcium bentonite was used as the inorganic binder. Silica sol and white latex can be selected for the organic binder.

(3)carrier liquid

The commonly used carrier liquid of lost foam coating is water or alcohol. Considering environmental protection and cost, water is mostly used as carrier liquid, and the coating made is water-based coating.

(4)surface active agent

In order to improve the coating of the coating to add a surfactant, it is both hydrophilic and lipophilic. Commonly used surfactants areJFC, full name polyoxyethylene alkyl alcohol ether.

(5)suspending agent

In order to make the refractory and binder fully mixed, so that it can be in suspension, the need to add a suspension agent. The commonly used suspending agent is calcium-based bentonite, which can also be used.CMC do water-based paint suspension agent. The use of bentonite andCMCMix for suspension.

3.2coating process design

There are four ways to apply the vanching mold coating: brush, dip, shower and spray. Because the castings are small and medium-sized thin-walled castings with complex shapes in batch production, spraying method can be used. The paint for lost foam casting is a water-based paint, and the viscosity of the paint will decrease during the stirring process, and the viscosity will increase after the stirring. Therefore, in order to obtain a uniform thickness, it is necessary to apply while stirring. At the same time, the speed of mixing the coating should be normal to avoid precipitation and the generation of gas. Apply evenly and do not expose.

The water-based paint needs to be dried after application. The paint is dried due toEPS model softening temperature limit, generally at low temperature or room temperature drying. Often40-60 ℃The drying time is2-10h. The humidity should also be controlled during the drying process, and the general humidity is less40% and ventilated to achieve better drying effect. Drying equipment is commonly used in drying chamber, drying oven and continuous drying kiln, heat source is electricity, heating, hot air and so on. And in the drying should pay attention to the following matters.

(1)The drying process requires the placement and support of the model to prevent the model from deforming.

(2)Must be dried thoroughly.

(3)After drying, it is necessary to place the appearance in a place with low humidity to prevent moisture absorption.

4Molding process

4.1Related design of buried box modeling

The sand is jewel sand. On the one hand, because the jewel sand has good fluidity, it is easy to fill up when vibrating, the compaction effect is good, the quartz sand has poor fluidity and cannot be filled in some places, which leads to iron-clad sand during pouring, thus reducing the casting accuracy. On the other hand, the breakage rate of jewel sand is low, and in the long run, it is appropriate to use jewel sand.

Approximate mesh number of molding sand20~40The sand is too fine and the air permeability is not good, which has a great influence on the surface quality of the casting. The sand is too coarse and easy to cause sand sticking and other phenomena. It is selected according to the actual production situation. Adopt rain sand. There is a quantitative material box at the bottom of the sand hopper. After the air cylinder pulls the valve plate, the sand flows into the sand box through the small holes evenly distributed on the valve plate. The size of the material box is basically similar to that of the sand box. The sand is added evenly and the impact force is minimum.

4.2vibration parameter design

The vibration parameters include vibration time, vibration direction, vibration frequency and amplitude. When packing, the direction and time frequency and amplitude of vibration should be selected according to the geometry of the foam pattern.

Usually choose high frequency low amplitude vibration, commonly used vibration frequency isAbout 50Hz to ensure that the dry sand is tight and does not damage the foam model. The amplitude is generally0.5~1.5mmVibration acceleration10~20m/s²。

5casting process

5.1gating system

Selection of top or bottom injectionThe process yield of top injection is higher than that of bottom injection.,The slag collection advantage of bottom injection is higher than that of top injection.

5.2negative pressure(vacuum degree)

Low, medium and high chromium alloy cast iron is -0.04 one.-0.05 MPa ,Other alloy grinding balls are selected within this range.

5.3pouring temperature

ductile iron1400-1450 ℃, even1480 ℃;alloy cast iron1450-1550 ℃,

high chromium grinding ball1520-1550 ℃.

5.4Pouring speed

Check the sand box pouringBefore the condition is correct, the pouring speed should be slow at the beginning, then turn fast, and finally take up the package slowly. StartE P SGasification and cracking products are discharged to the gate cupIt should be prevented from splashing.Later, E P S gasifies to form a channel, sealing the sprue and making the mold sealed.,Maintain its vacuum,Pouring smoothly. Finally, in order to make the gasification residue and impurities have sufficient time to float to the top.,allow gas to escape,Slow pouring,But pouring stream fine-Coarse-Fine cut can not be interrupted.

5.5Voltage stabilization and unpacking

Vacuum pump continues to pump negative pressure after pouring3~5 m in, but when pouring low chromium grinding balls, in order to achieve the cooling speed of metal mold casting and cast hard layer, some plants also use in the austenite area.(Under as-cast red heat)For normalizing, the method is blowing, blowing and spraying, blowing and spraying fine water.(Turn the ball string), Improve hardness and increase anti-wear performance.

6Possible defects and prevention

6.1Collapsed box

Cause:

Excessive buoyancy of pouring liquid metal; Excessive gas pressure in the mold; Hollow or insufficient strength in the pattern; Internal flow and impact of liquid metal; Internal damage of sand box moving mold, etc.

Preventions:

(1) Reasonably control the pouring speed to ensure that the pouring cup is always filled with metal liquid and cannot be cut off during the pouring process.

(2) Appropriately increase the size of the negative pressure to make the sand more compact.

(3) Choose a low-density appearance to reduce gas generation.

(4) choose high strength, good air permeability coating.

(5) The vibration molding process parameters should be reasonable to ensure that the dry sand everywhere is compact and uniform.

6.2Cold insulation, insufficient pouring

Cause:

The filling temperature is too low; the pouring system, structure and pouring operation process are improper, and the negative pressure during the filling process is too large.

Preventions:

(1) Increase the pouring temperature of liquid metal.

(2) Improve the gating system and increase the filling speed.

(3) Adopt appropriate negative pressure.

6.3Backspray

Cause:

Insufficient negative pressure is the root cause of backspray. There are many reasons that affect the degree of negative pressure, including the pattern density is too large, the dry sand has poor air permeability, the coating has poor air permeability, the pouring temperature is too high or the pouring speed is too fast, etc.

Preventions:

(1) select the appropriate dry sand molding, in order to control the permeability of dry sand, do not mix different grades of mesh dry sand.

(2) Control the pouring temperature and pouring speed, that is, the filling temperature to ensure the gasification of the pattern.

(3) reasonable control of the coating thickness, improve the permeability of the coating, so that the gas is discharged in time after the gasification of the pattern.

(4) Reasonable design of the gating and risking system to ensure that the metal liquid fills the cavity smoothly and quickly during pouring.

6.4stomata

(1) The main reason for the generation of a kind of porosity in castings is that air is involved in the injection of high-temperature liquid metal, and the involved foam debris will be vaporized by the liquid metal to generate gas. The air cannot be effectively discharged from the casting mold, thus remaining in the casting mold. This kind of pore treatment method is to reduce the pressure in the sand box appropriately.

(2) casting another pore caused by the main reason is because of the coating: poor permeability of the coating, and the coating layer is too thick, so that the pattern after vaporization of the gas can not be completely excluded from the mold in a timely and effective manner, the residue in the mold.

6.5shrinkage porosity

Under the action of liquid metal at high temperature, the white mold vaporizes and disappears, and the molten metal occupies the space of the white mold. When the high-temperature liquid metal cools down and becomes solid, volume shrinkage will occur. When the high-temperature solid metal cools to room temperature, there will be solid shrinkage. The solid shrinkage of the metal will cause the change of the outer contour of the casting. After the liquid metal solidifies and shrinks, the new liquid metal will be blocked and cannot enter.

7Concluding remarks

Although the lost foam casting grinding ball does not have the metal mold casting shell to resist wear, due to the uniform cooling speed, the metal mold casting grinding ball will not wear first at the gate and riser, which will affect the output of the ball mill.Based on the experience of many manufacturers, the diameter of the lost foam casting grinding ball should be 30-120mm in diameter. Diameter less30mmBecause the heat of the alloy liquid is insufficient for gasification and cracking, it is easy to cause carbon deposition, wrinkling and slag inclusion.(carbon black); The diameter of the grinding ball is greater120 m m, it is easy to cause the center to be loose and hollow. In short, the lost foam casting grinding ball process is constantly adapting to the development needs.

Related News