Process design of lost foam casting for wall plate of sintering machine

Release time:

2021-12-06 14:18

Source:

1. Foreword

Our company completed the process pouring work on a vertical cooling site in Anyang. Before the introduction of the lost foam process, the site used water glass sand for modeling. The surface quality of the cast castings was poor and the sand sticking was serious, especially for the core sand. Lost foam casting is also known"Dry mold casting", with dry sand as molding sand, by the buried box vibration and pouring when the extraction of negative pressure to make dry sand fastening outside the white mold coating layer to form a mold, pouring with iron liquid replacement white mold to obtain casting.Pouring Square of PiecesLaw[1].

Lost foam casting started in China.In the 5. sixties of the 20th century, it was only in the stage of vigorous development in the past 20 years. At this stage, under the premise of national energy conservation, emission reduction and environmental improvement, lost foam casting is being accepted by more and more enterprises, lost foam casting process is in a state of popularity, more and more castings need to develop a reasonable lost foam casting process, which has become an urgent problem for every lost foam practitioner to solve.[2]. It is worth trying to absorb the benefits from the traditional casting process and formulate a reasonable lost foam casting process.[3].

2. Casting Analysis

Sintering machine wall plate is an important workpiece on the sintering machine, for high chromium heat-resistant parts (whichCr content can reach about 20), the middle two pipes are cooled by water, which requires no water seepage, high surface quality requirements, no defects such as pores, slag holes, shrinkage porosity, etc., and processing is required to ensure coordination. The quality of the single casting is nearly 700Kg, the outline size is 2000 × 168 × 320(mm), the middle part has two through holes 30 26mm, and the lower part of the casting has a blind hole with a depth of 30mm.

3. Casting process analysis

The main difficulty in the application of lost foam casting on the casting is that there are two through holes in the middle part.30mm and 30 deep blind holes in the lower part. For blind holes due to the use of castings, they must be downward. In order to prevent the occurrence of iron-coated sand, pre-filling is required. As for the through hole, due to the small size and long length, defects will definitely occur if only dry sand is not processed. First refer to the original process of the plant.

The site originally used the water glass sand casting process, the basic process includes: mixing sand.-Mould making-lower core-mould closing.

After mixing fine quartz sand with water glass in the sand mixer, fill it into the casting pit. First, fill in a certain thickness of water glass sand around it as a reinforcement layer. After putting it into a wooden mold, fill in water glass sand layer by layer and fully tamping it. After taking out the wooden model, first repair the model, especially the lower boss. After the pouring system is completed, the hole is tied.CO2Curing is carried out, and the floating sand inside is blown out after curing. With inner diameterBoth sides of the 26mm iron pipe are supported by iron plates as cores. In order to prevent the molten iron from excessively scouring the iron pipe at the inner gate, two 20mm thick iron plates are specially welded on the two inner gate iron pipes. Use an iron sandbox as the gate and two bright risers on the flat plate, and after the mold is closed with the previous model, the gate can be corrected. After sealing around, the upper stone is ready for pouring. The main processes are shown below.

4. Lost foam casting process

(1) White area

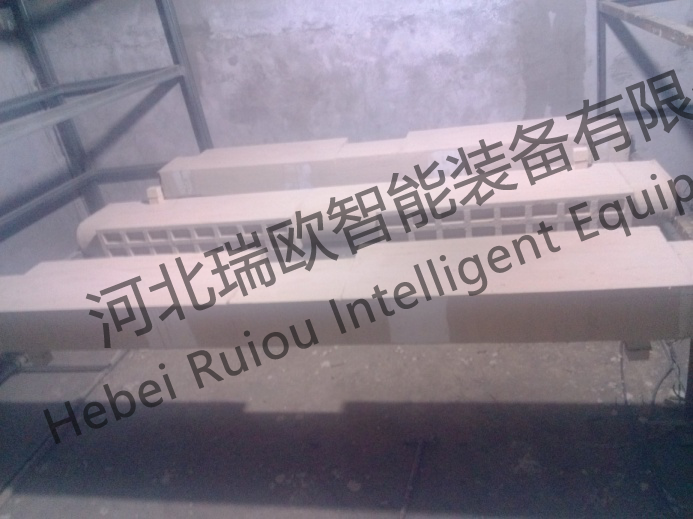

Due to output constraints and casting shape, the site is easy to use hand-cut white mold. Density of white-molded benzene board18~20g/L, fully dry. The white mold is obtained after cutting the lower plate. Referring to the traditional water glass sand casting process, steel pipes are also used as through holes, and steel pipes are put in when bonding white molds.

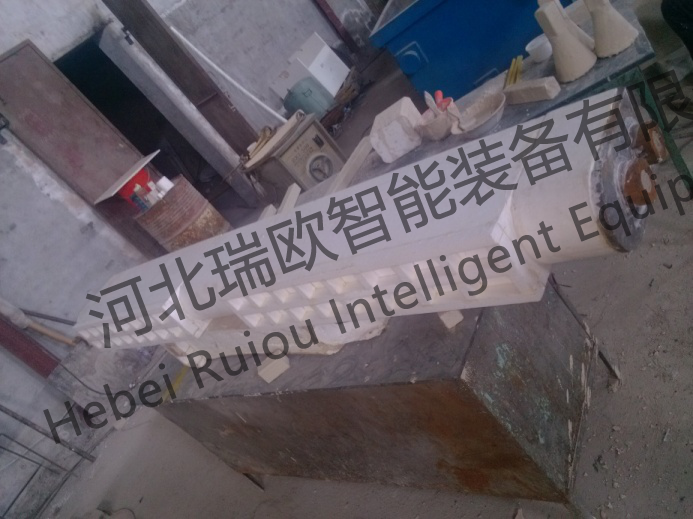

The casting gating system adopts side top injection, and the size of the inner gate is50 × 50mm, in order to prevent steel pipe penetration, 20mm thick steel plate is welded to the steel pipe at the inner gate. After the steel plate is welded in place during the bonding of the white mold, the white mold is repaired. In order to prevent a large amount of gas generated by the glue during the bonding process, the amount of glue used is controlled. The two ends of the steel pipe are fixed with iron sheets to prevent the deviation caused by the impact of the molten iron on the steel pipe during the pouring process. The white mold bonding is shown in the figure.

(2) Yellow Zone

After the cast steel coating is fully stirred, it is put into the coating tank to brush the white mold. The white mold shall be painted three times. After each time of painting, it shall be put into the drying room and fully dried. The drying room shall pay attention to moisture removal. Due to the use of quartz sand for the sand, white mold coating thickness of upAbout 2mm to prevent sand sticking. After the third brushing, use quartz sand (200 mesh), glutinous rice flour, alcohol, PVB and other mixed materials to pre-fill the blind hole. The box can be buried after being fully dried.

(3) Black area

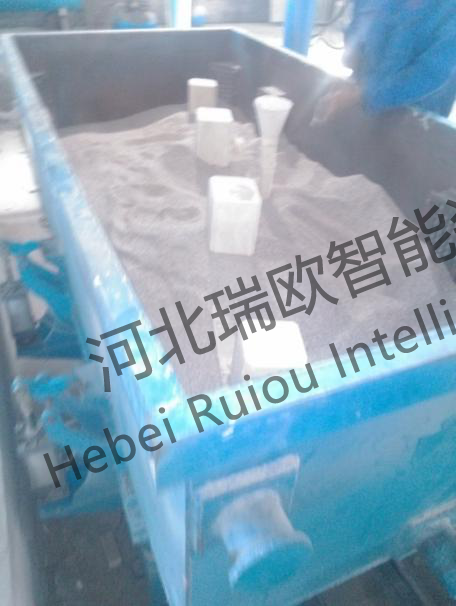

The site uses our company's mobile vibrating table, which is used with rain shower and sand adding device to facilitate the modeling of buried boxes. After the white mold is dried, the buried box modeling work will be carried out. First, put the sand box on the vibrating table, and then open the rain sand dispenser after clamping. Bottom sandAfter about 200mm, turn on the vibration motor to vibrate. After the bottom sand is vibrated, put the white mold into the sand box with lifting tools, and add sand in layers for vibration. After the sand box is filled (the riser is at least 100mm from the top sand surface), cover the film and add surface sand. Water glass sand shall be used for protection around the pouring cup to prevent sand washing. Buried box process as shown in figure.

When the molten iron temperature reaches,Open the negative pressure system before pouring, and control the negative pressure-0.050MPa. After pouring the molten iron in the molten iron, open all the butterfly valves in the sand box, and adjust the negative pressure to 0.015~0.02 for 20min.

When pouring, pay attention to pouring speed control, general rhythm: slow-Fast.-Slow. In the case of molten iron is not backsprayed, try to speed up the pouring speed, try to control within 40s. The next morning, the site was unpacked and kept warm for about 14 hours. After unpacking, it was sent to the shot blasting machine for casting cleaning. as shown in the following figure.

5. Conclusion

Through the on-site trial pouring, the above-mentioned process flow is basically satisfied with the qualified casting products, and can ensure a high rate of genuine products. Reasonable casting process is a prerequisite for obtaining qualified castings. As a new casting method, lost foam casting is gradually being accepted by the industry, and its share is gradually expanding. Castings produced using traditional casting types are being tried to be replaced by lost foam casting. But the traditional casting form is definitely beneficial to the design of the lost foam casting process. Traditional casting forms exist for thousands of years, has been promoting the progress of society, there are a lot of things is worth absorbing, so in the design of lost foam casting process, may wish to refer to the traditional casting process.

However, there is still a certain difference between lost foam casting and traditional casting. We should also consider it when designing the process plan. For example, foam occupies the cavity and a large amount of gas generated by gasification needs to be discharged. The fluidity of molten iron will be reduced due to quenching after encountering foam and negative pressure. Negative pressure will affect the flow direction of molten iron and eventually lead to a different place for final solidification from traditional casting. Wait.

Previous Page

Next Page

Related News