Chapter Four Black Zone Process 4.5 Molding Equipment

Release time:

2022-03-22 16:31

Source:

4.5 styling equipment

Today, our lesson is mainly about molding machine and negative pressure system. First, we will briefly introduce the casting process of lost foam. First, we have to bury sand for molding, that is to say, add bottom sand and vibrate first, then put the white mold into the sand box, add sand and vibrate firmly, and finally add plastic to seal the sand and put the pouring cup. This is a molding process. Casting can be carried out after molding, lost foam casting is to be in the vacuum state of casting, so each in the lost foam production site essential two equipment is the seismic table and negative pressure system.

The vibration table equipment is used to vibrate the sand in the sand box during the production of the lost-vanity model, so that the sand in the sand box has sufficient filling firmness.

The filling and vibration compaction of molding sand is one of the most critical technologies of lost foam casting, and it is also one of the difficulties of lost foam casting technology. Because the lost foam castings have complex surface and cavity structure,EPS has the characteristics of softness, thinness and easy deformation. Lost foam casting technology has unique modeling process requirements. Dry quartz sand or jewel sand with 20-40 mesh is used as molding sand for modeling. No adhesive is added in it. Sand filling and seismic compaction methods are adopted. It is required that the coating on the surface of EPS model shall not be damaged and the accuracy of its size shall be ensured within the specified time. Under the premise that the model is not deformed, quickly fill the sand in each part of the sand box evenly around the EPS model and reach the compactness required by the process. Throughout the modeling process, the effect of vibration and compaction directly affects the finished product rate, dimensional accuracy, surface quality and product quality of lost foam castings, so he determines the success or failure of the casting process.

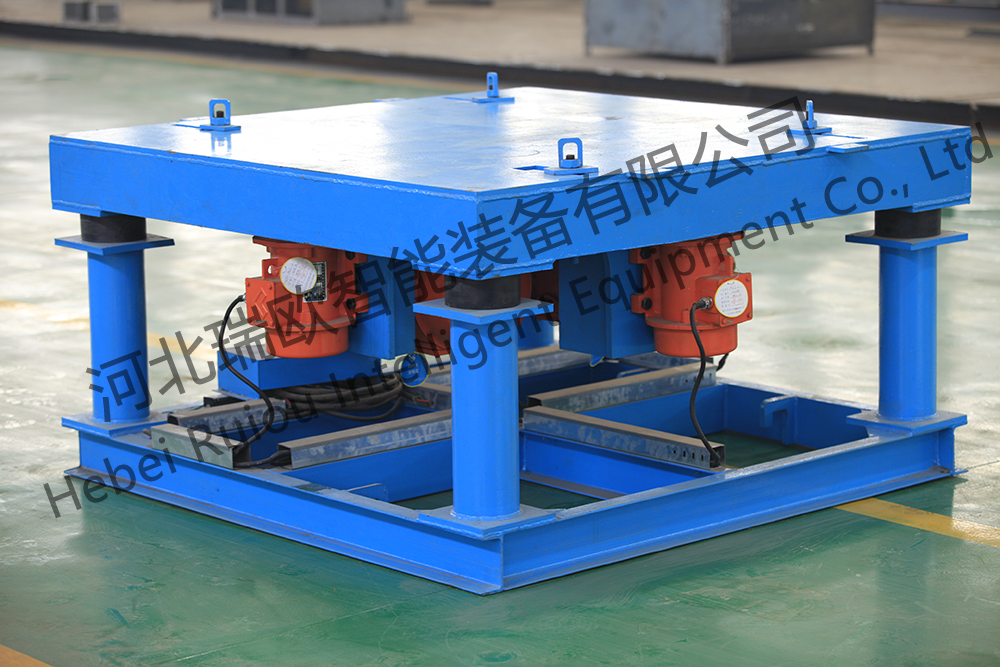

4.5.1 Introduction of vibrating platform

At present, there are three types of seismic platforms commonly used: three-dimensional seismic platform, suspension excitation, and clip-on seismic platform.

Let's talk about this most commonly used three-dimensional seismic table: the general three-dimensional seismic table uses a cylinder to clamp the sand box. In actual use, the air spring rises or the rubber spring plays a seismic isolation role, and the four horizontal vibration motors can produceX-direction and Y-direction vibration, while the bottom of the two motors can produce Z-direction vibration, a total of 6 vibration motors, which we often say three-dimensional seismic platform.

1 Fixed vibrating table

1.Use

This kind of seismic platform is the simplest kind of three-dimensional seismic platform, using rubber spring combination for seismic isolation, using compression block,For vibration motorGroup 3:Channel steel base, the bolt pressure rod is composed of manual compression. For electrical control, we have connected the vibrating table motor line to the terminal according to the circuit diagram. In the control cabinet, it is also connected to the wiring terminals according to the circuit diagram.

2、Direction of motion of amplitude

As shown in the above figure, the amplitude generated by the bottom vibration motor is vertical up and down, and the side vibration motorThe amplitudes of the side-shaking motor 1-1 and the side-shaking motor 1-2 are in the Y horizontal direction, and the amplitudes of the side-shaking motor 2-1 and the side-shaking motor 2-2 are in the X horizontal direction.

3、Adjustment of exciting force

The excitation force and amplitude are adjusted by adjusting the angle of the eccentric block of the vibration motor or by frequency modulation.

This kind of seismic platform is generally used in a small production line with a small investment and a low output basic configuration.

2 Airbag clamping vibrator

Main structure of vibrating platform16mm thick steel plate is welded, 6 excitation motors are installed on the vibrating table, jacking airbags are installed on the upright column for lifting the vibrating table, and a cylinder clamping mechanism is installed on the upper part for clamping the sand box. For electrical control, we have connected the vibrating table motor line to the terminal according to the circuit diagram. In the control cabinet, it is also connected to the wiring terminals according to the circuit diagram.

1. Equipment control process

The working state of the airbag vibrating table is controlled by the control cabinet. When the sand box stays on the vibrating table, it inflates into the airbag through the air path, and the lifting bracket lifts the sand box upward and disengages from the track. During this process, the cylinder works to clamp the sand box, and then the vibration motor starts to work, so that the vibrating table produces a three-dimensional vibrating effect. The sand in the sand box achieves the expected effect.

2. Main functions and advantages

1. 2. Advantages: ① The airbag is lifted and the cylinder is clamped to the sand box to transfer the excitation force to the sand box to the greatest extent; ② It has the function of frequency conversion adjustment to adjust the vibration force, which is used for different structures and thin The vibration of thick parts; ③ Three-dimensional vibration, good vibration effect, high production efficiency, vibration frequency adjusted by frequency converter, simple operation and easy maintenance.

3、Operating Instructions

The whole working process of the airbag vibrating table is completed by the control cabinet controlling each working element. The operator only needs to control the control button on the control cabinet to realize the working process of the vibrating table. At the same time, the frequency of the vibration motor can be adjusted by changing the input data to make the vibrating table produce different vibrating effects.

This kind of seismic platform is mainly used for vibrating the sand in the sand box when modeling on the general rigid production line.

According to the needs of different customers, on this basis, we have developed a bottom seismic platform and a mobile seismic platform.

The overall dimensions of the bottom shock platform are similar to those of the airbag shock platform, and the motor control only controlsZ direction vibration, mainly used to separate lines, speed up the modeling speed.

The principle of mobile vibrating platform is the same as that of airbag vibrating platform, adding mobile equipment. The combination of car ferry and airbag vibrating platform is mostly used in combination with sand storage bucket and rain shower sand dispenser, which can be completed at the same time.It is mainly used for flexible production lines.

4 Suspension shock vibration platform

At present, the three-dimensional vibrating table is generally used for the modeling of lost vanity formwork. The sand box filled with molding sand is vibrated on the vibrating table. The sand box is clamped by a clamping device. The three-dimensional vibrating table vibrates in six directions of up and down, left and right, front and back with three groups of six motors. The disadvantage is that whenWhen the EPS model is more complex, it can not achieve all-round seismic reality, prone to dead corners, low efficiency is difficult to meet the requirements of the lost foam process.

The suspension excitation seismic table changes the three-dimensional vibration mode of filling sand in the past. The sand box is placed on the jacking column without clamping (the number of jacking columns is determined according to the sand box). There are only two vibration motors equipped with gravity sensors, which can detect and automatically adjust frequency according to the gravity sensors to achieve appropriate vibration acceleration. In the process of adding sand, the gravity and center of gravity of the sand box change, and the load of the molding machine changes. To achieve a better seismic effect, suitable vibration acceleration is required. The vibration acceleration is proportional to the vibration frequency. According to the feedback signal detected by the gravity sensor of the molding machine, the frequency of the vibration motor is automatically adjusted to meet the requirements. To make up for the lack of traditional modeling vibration table for complex parts of the low efficiency difficult to shape. The suspension omni-directional shock molding machine is the reverse filling of vertical movement, which can reach the vibration of different parts in all directions and the filling of various dead corners. It has the characteristics of high frequency, low amplitude and high seismic efficiency.

Clip-on seismic platform

In the lost foam casting process, with the increase of casting types and complexity, the requirements for the seismic table of the host equipment of the lost foam casting process are getting higher and higher, especially the filling of the casting structure with horizontal blind holes, grooves, vertical grooves and other molding sand, because the vibration direction of the current seismic table is relatively single, the change of vibration direction cannot be completed during the seismic process, the filling properties of the molding sand in these structures cannot be satisfied.

Clamp-type seismic platform by lifting the sand box suspended vibration, throughThe PLC controller controls the eccentric block and phase angle of each vibration motor to complete the change of various vibration directions, and the vibration frequency and amplitude are adjustable. This seismic platform is equipped with a gravity sensor, through the gravity sensor control can also control the sand speed, adjust the excitation force and amplitude.

Precautions for the use of equipment

1.Equipment must be reliably grounded, safety first. In case of an accident.

2.Do a good job in daily normal use and equipment maintenance, just like even if you buy a good car, he also needs regular maintenance.

3.Regularly check the fasteners of key parts of the equipment. Because it is a vibration equipment, if it is loose after a long time, it must be fastened well.

4.Regular maintenance of bearings. Normal working bearing1 time/month. Clean the bearing at least once a year and replace the lubricating oil.

5.In order to prevent the airbag from over-expanding, there is a limit guide post in the airbag. Improper operation will cause the limit guide post to break when hitting the vibrating table. The vibrating table airbag will over-expand, rise higher than usual, and shake unsteadily. At this time, the airbag should be removed and the guide post should be replaced.

After that, the seismic platform told us a story. In one of our sites, we gave the customer the key and completed the project with good quality and quantity. However, after a period of time, the customer feedback said that the power of your seismic platform was too small to be true. We recalculated and checked our equipment, and found that there was no problem with our seismic platform, because the products on each site were different, the sand box was different, and the seismic platform was also different, the seismic platform is also different from each site, so we are customized for each seismic platform. Therefore, our unit sent technicians to the site to deal with it and found that the customer had added the seismic platform again.Two vibration motors, the vibration time is shortened by the customer, so the vibration is not real. There is a misunderstanding among most people: the larger the vibration motor, the greater the vibration force and the better the vibration effect. In fact, this is wrong. Everyone knows that the vibration motor has the function of vibrating and transporting. For vibrating and transporting, it is best to control the exciting force at about 1.5. If the exciting force is too large, the sand will not be shaken and scattered.

Related News