Chapter Four Black Area Process 4.3 Lost Molding Sand Treatment System

Release time:

2022-03-19 13:14

Source:

What we are talking about now is the treatment of lost matrix sand. So, we give the sand treatment to define a range, to use the lost foam process for casting. When we mention the lost foam, we always say that this is a green casting. So green casting lost foam sand treatment, what role do we need to meet? This is a problem we need to study today.

4.3.1 The role of lost foam sand treatment

Let's first review the lost-form production process.

According to the process requirements, first we find a container, sand box, put in the model cluster, then add sand, and bury the model cluster with sand. Next, we need to ensure the compactness of the sand. We need a vibrating table to shake the sand and finish the modeling. Finally, the casting is poured, cooled, the casting is taken out, and the casting process is completed.

At this time, if I want to start the next process, I still need to use sand box and add sand. But now there's something left in the sand box. What do you have? A box of sand after taking out the casting. The sand box should be emptied and the sand should be recycled.

First action, pour out the box of sand. That is, the first function of the sand processing system: turning over the box.

1. Turn over the box: use the turning over equipment to pour the castings and sand from the sand box.

After turning over the box, we will use the sand when we bury the box for the second time. The sand in the sand box is directly in contact with the casting, due to the heat exchange function, the temperature of the sand will be very high, sometimes can reach 3. four hundred degrees. And the material of the model cluster, inIt will shrink and melt at 70 degrees. If the sand temperature is too high when we are modeling, it will cause the model cluster to deform and cause waste parts. Before reuse, the sand temperature must be reduced to about 50 ℃. This is the second function of the sand processing system: cooling.

2, cooling: the hot sand cooling treatment, the sand temperature to 50 ℃ below, so that it reaches the molding sand filling technical requirements of the specified temperature range.

When the cooled sand is used again, it will be found that there are some impurities in the sand and it is not clean. There will be several things in there. There are iron beans formed after the solidification of molten iron splashed during pouring; there are pieces of paint skin falling off the surface of the casting after pouring; there are pieces of sand crushed to form; there are dust formed after the paint is crushed. These impurities are included in the sand and will have a certain impact on the casting. We must get rid of these impurities. This is the third function of the sand treatment system: impurity removal. Here also contains two aspects, slag and dust removal.

3. Slag removal: screen out iron blocks, films, paint skins and other sundries in the molding sand. Magnetic separation removes iron beans, iron powder, etc. in the sand.

Dust removal: remove the dust mixed into the sand after the coating layer is broken and the sand is broken. At the same time meet the national environmental requirements.

After we turn out the sand, after a series of treatment, remove impurities, reduce the sand temperature, sand can be used again. We'll have to transport the sand back to the modeling point. At this time, the conveying function of the sand treatment system is required.

4. Conveying: including horizontal and vertical conveying, to realize the whole conveying from the sand drop point to the packing position.

In the whole sand treatment process, we need to use a variety of equipment, at this time, the connection and cooperation between the equipment is very important. Moreover, due to the different operating frequencies and operating conditions of the equipment, it is even more necessary for some equipment to play a buffering role to prevent mutual interference and constraints between processes. At the modeling point, the modeling is intermittent sand work, and the transportation is indeed a uniform transportation state. At this time, a certain amount of sand is required to be stored to ensure that it is available as needed. If there is too much sand, we also need to store it.

5. Storage: including process storage and final storage.

reach aboveFive functions, let's take a look at the current workflow.

Turn over the box and drop the sand→ deslagging → cooling → conveying → storage, to be shaped. At the same time to ensure the whole dust.

We can say that meet the above5 functions, is a set of qualified vanishing mold sand treatment system.

4.3.2 Introduction of common equipment of sand treatment system

1、Automatic box turning machine (box turning equipment):

Main functions

(1)The operation is simple, human resources are saved, the whole process is unattended, the whole process of turning the box is automatically carried out with the sand box in place, and all actions are controlled by the signal feedback device;

(2)It can realize the online box turning, without lifting the online sand box from the production line, and the sand box automatically falls back into place after turning over.

(3)Box high frequency, improve work efficiency.

(4)Save time, the castings and sand in the sand box on the running line are turned over without leaving the running line, so that the running line is seamlessly connected with the sand treatment line.

2、Horizontal cooling machine (cooling equipment):

Main functions

(1)Function: cooling, conveying sand, sand dust removal.

(2)Large amount of sand cooling: to ensure that the sand reachesBelow 50 ℃. Single machine high efficiency.

(3)Good dust removal effect: the lifting material structure is designed reasonably, and the molding sand is raised to the greatest extent. Sand dust is removed by axial flow fan and dust collector.

(4)Energy saving: the power of the equipment is only twoIt is composed of a 5.5KW motor, a 7.5KW water pump and a 0.55KW fan. The energy consumption is quite low, reaching the same sand processing capacity, and the boiling cooling bed needs 74KW.

(5)Suitable cooling medium: the cooling medium is mainly water, with large specific heat capacity, taking away the most heat per unit volume, fast cooling speed, convenient access, and recyclable. Wind is the second medium. The sand raised inside the equipment is blown up by the rear fan to raise dust, and the front dust removal port is pumped away. The dust removal efficiency is high and a large amount of heat is taken away.

(6)The frequency conversion control of the equipment can adjust the running speed of the molding sand in the horizontal cooling machine according to the sand temperature to achieve the effect of temperature control.

(7)Node temperature control, effective detection and control of sand temperature.

(8)The equipment runs smoothly, does not vibrate, and has a firm structure, which greatly reduces the failure rate of the equipment.

3、Vertical cooling machine (cooling equipment):

Main functions

(1)Function: cooling, lifting, spiral vibration conveying.

(2)Cooling method: air cooling, to ensure the cooling temperature of the sand.

(3)The molding sand can be removed from150 ℃ to below 50 ℃.

(4)Lifting: The equipment has a lifting function, which can save money in the sand treatment production line.1 chain hoist.

(5)Occupying area: The equipment occupies a small area, saves space, and is suitable for small-scale production lines.

4、Sand temperature regulator (cooling equipment):

Main functions

(1)Sand temperature regulator adopts close-packed seamless steel pipe to realize sand heat exchange, with large contact area and high cooling efficiency.

(2)The machine covers an area of small, large heat dissipation area, good temperature effect.

(3)The sand temperature of the sand temperature regulator can be displayed, and only the molding sand that meets the temperature requirements can be sent to the next process.

5、Casting Separator (Slag Removal Equipment):

Main functions and advantages

(1)Quickly separate the molding sand from the casting through the sieve plate and the drop hopper, and send the casting out of the casting separator, and collect the molding sand and enter the next process;

(2) The upper part of the casting separator is equipped with a sand falling chamber and a dust removal system to reduce dust pollution and ensure the working environment;

(3)Reduce the labor intensity of workers, cooperate closely with the whole production line, and improve production efficiency.

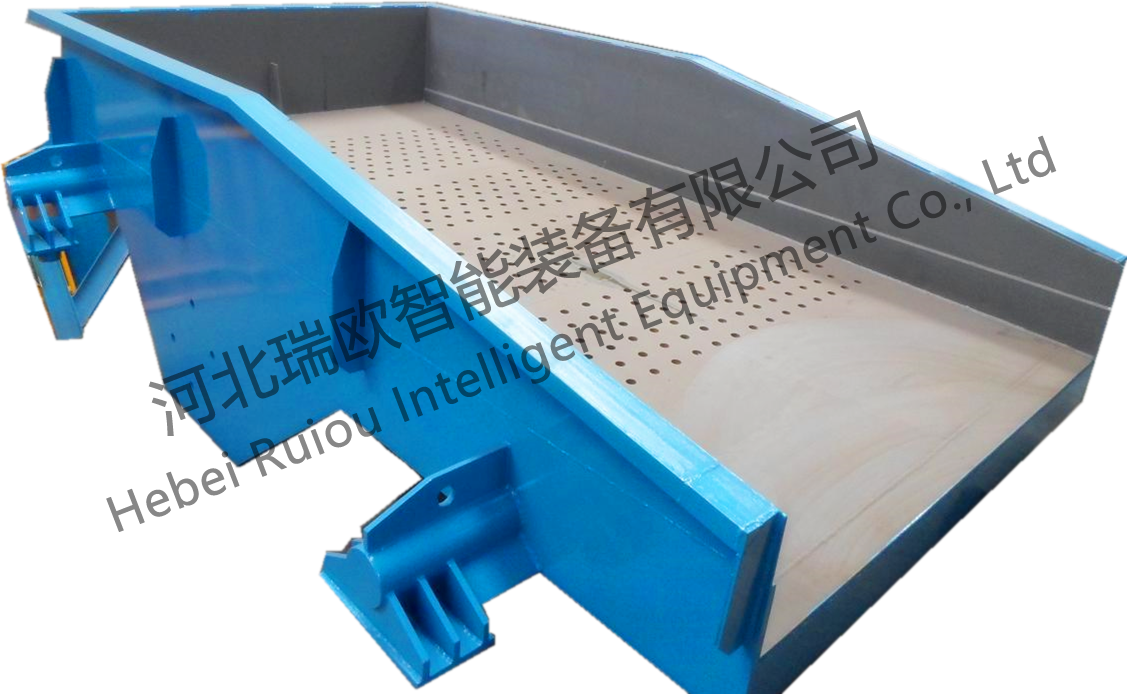

6、Screening conveyor (slag removal equipment):

Main functions and advantages

(1)Conveying function: Screening conveyor is used to screen the sintered paint fragments in the old sand, iron beans and other sundries.

(2)Cooling function: long material screen dripping line, built-in air cooling system, can quickly and efficiently reduce the temperature of molding sand, is our factory specially designed for dry sand negative pressure casting production supporting the development of an efficient and energy-saving sand screening equipment.

(3)It has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration and noise, sturdiness and durability, convenient maintenance and safe use.

7、Magnetic separator (slag removal equipment):

Main functions

Remove the residual metal in the casting sand in production. Avoid the unfavorable factors of iron beans on castings when modeling.

8、Dust collector (slag removal equipment):

Main functions and advantages

(1)The dust collector is mainly used to treat the dust of each node in the lost foam sand treatment system.

(2)The fan brings the dust into the dust collector, the dust is filtered by the internal dust removal device, and the filtered clean gas is discharged into the atmosphere from the fan outlet to meet the national environmental protection requirements.

(3)With the cyclone dust collector can better strengthen the dust removal effect.

9、Hoist (conveying equipment):

Main functions

(1)Function: to enhance granular and small non-abrasive and semi-abrasive materials.

(2)The chain has high temperature resistance, high yield strength and good elastic deformation, which is suitable for high temperature conditions.

(3)It is connected with the dust removal system to enhance the dust removal effect of the overall system.

(4)Including automatic detection alarm device, improve the overall equipment automation control level.

10、Belt conveyor (conveying equipment):

Main functions

The belt conveyor conveys pieces or bulk materials, mainly used to convey dry sand to the sand storage hopper, and its working environment temperature is generally limitedBetween -10°C and 70°C. Can be used for horizontal or inclined conveying.

11、Pneumatic conveying system (conveying equipment):

Main functions

(1)Function: conveying molding sand.

(2)Dense phase dynamic pressure pneumatic conveying is intermittent conveying form, material and compressed air for intermittent continuous arrangement.

(3)It is composed of feeding bin, bin pump body and pipeline, with simple structure, reliable operation and simple operation.

(4)The material runs in the closed pipeline, fully sealed, no leakage, no dust, clean and pollution-free environment, which meets the transportation requirements under various conditions and greatly reduces the pollution degree of the foundry.

(5)The pipeline layout is flexible, the floor area is small, and it is not restricted by the space layout of the site, nor does it hinder the arrangement of other equipment.

(6) The molding sand is transported smoothly, the running speed is medium, the noise is low, the impact is small, the wear is small, and the equipment service life is long.

(7)Economic and reasonable, low cost, low energy consumption. The power of the equipment only needs compressed air and does not need other electric drive. According to the site layout experience, this equipment can replace1 belt hoist, 1-2 belt conveyors, from the equipment investment and power are saved.

12、Sand hopper (storage equipment):

Main functions

The sand storage hopper is used to store the molding sand passing through the sand treatment system, with a built-in level gauge. The height of the molding sand reaching the level gauge detection device has automatic alarm and shutdown functions, which is reasonably combined with the whole sand treatment line.

Related News